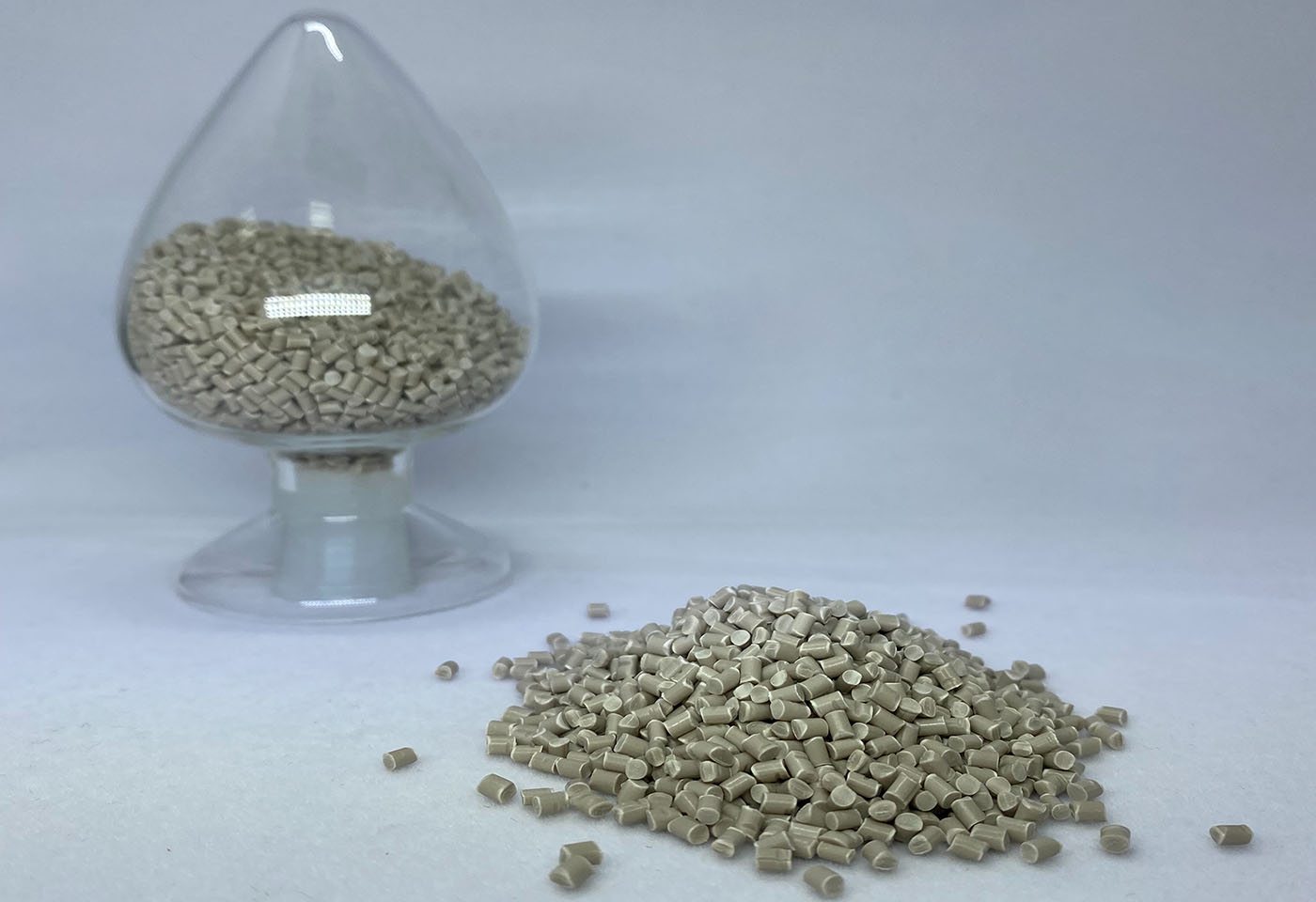

Sea Shell Powder Masterbatch

Our natural anti-bacterial oyster shell powder masterbatch is able to make various products included daily-used products like hair dryer, earphones, electric toothbrushes, suitcases and toilet seat.

It can also be used to make home appliances and kitchenware. (Home appliances: vacuums cleaning, air purifier, air conditioner and water purifier. Kitchenware: coffee makers, food processer, mixer and cutting board.)

PP/PE/PLA Base

Sea Shell Powder Masterbatch

Customized Service Available!

Other plastic based masterbatch can be customized according to your needs, e.g., EVA, PC, PS, PVC, ABS, TPU.

Application: sandals, slippers, sneakers, hiking boots, flooring products, medical hospital bed, suitcases, stationery, dental floss sticks, wound dressings, surgical gowns, catheters, gloves, brand logos, waterproof and moisture-permeable fabrics, sofa seats, military water bags, life jackets, sound insulation, PC cases, power supplies, rice cooker, toaster, coffee grinder, water filter, electric toothbrushes, hair dryer, brushes, curling wand, flat iron.

Biodegradable Impact Modifier

Impact modifiers used to improve the impact performance of engineering plastics, such as polyesters, polyamides and polycarbonate blends. They provide an excellent balance of impact resistance, modulus and viscosity with an extraordinary good retention of heat distortion temperatures.

Bio-plastic, however, has inferior properties than normal plastic including the impact strength & flexure modulus, which make it indispensable to use the impact modifier during the production.

Furthermore, it could be difficult to well blend different bioplastic.

For example, normally, PLA (Polylactic Acid) is not compatible with PBS, PBAT & other filler like cornstarch. In this case, our impact modifier could also work as compatibilizer between different materials.

Plant Fiber Reinforced Material

Aquaculture is a well-developed industry in Taiwan.

Oyster is the major products of aquaculture in the west of Taiwan, and it yield 160 thousand tons of waste oyster shell every year which is a serious pollution source.

BACK TO BASICS recycled these waste materials, and turn them into valuable material. We follow our faith to be zero waste & environmentally friendly.

Recycle: We collect waste natural resources like rice husk & oyster shell.

Reuse: We combine the rice husk powder & oyster shell powder with PP or biodegradable material, and we make them into 2 grades: extrusion & injection.

Reduce: Using plant fiber could significantly reduce the carbon emission during the productions, which is no doubt a key action toward our goal of being environmentally friendly.